Huiya Envirotech’s expertise ensures optimal application of Chlorine Dioxide’s strong oxidizing and broad-spectrum antimicrobial properties, maintaining clean, safe, and efficient power plant systems while upholding stringent environmental standards. Our commitment to innovative water treatment solutions helps power plants operate reliably and sustainably, delivering superior performance in water and gas management processes.

Sodium chlorite and chlorine dioxide are essential for efficient water treatment in the power industry. These compounds are used in cooling water treatment to control biofouling and legionella, wastewater treatment for disinfection and odor control, and flue gas treatment for NOx and cyanide removal. Chlorine dioxide’s powerful oxidizing properties help maintain system efficiency, safety, and environmental compliance.

Sodium chlorite water treatment plays a vital role in maintaining the efficiency and longevity of water systems in power plants. This versatile compound is widely used in cooling water treatment and wastewater treatment to control microbial growth, prevent scaling and corrosion, and ensure compliance with environmental standards. Sodium chlorite is often preferred over traditional chlorine due to its reduced production of toxic byproducts.

01 / 02

In power plants, cooling systems are critical for maintaining operational efficiency. Effective cooling water treatment with sodium chlorite prevents problems such as microbial growth, scaling, and corrosion.

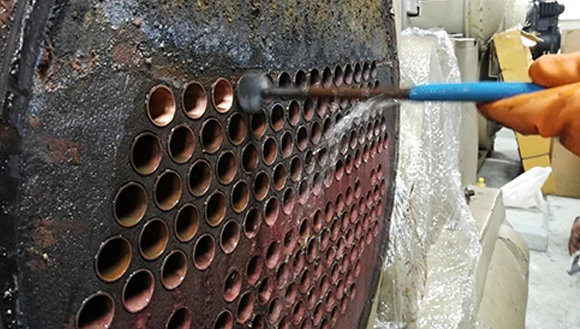

Microbial Control: Sodium chlorite, when activated to form chlorine dioxide, helps control microbial growth in cooling water systems. This includes inhibiting biofilms, algae, and bacterial growth in recirculating cooling towers. Biofilms can significantly reduce the efficiency of heat exchangers and increase corrosion risks. Chlorine dioxide penetrates and eradicates these microbial contaminants, maintaining system performance.

Scale and Corrosion Inhibition: Sodium chlorite contributes to scale and corrosion control on equipment surfaces in cooling water systems, helping to maintain system efficiency and prolong the life of cooling tower components.

Oxidation of Contaminants: Activated sodium chlorite breaks down organic materials and some metals in the water, ensuring contaminants are effectively removed. This oxidation process helps maintain water quality and system efficiency, ensuring optimal operation of the cooling system.

02 / 02

Sodium chlorite is also highly effective in wastewater treatment at power plants. It provides several benefits for disinfection, odor control, and the reduction of harmful contaminants in wastewater.

Disinfection: The chlorine dioxide produced by sodium chlorite is an effective disinfectant. It destroys bacteria, viruses, and other pathogens, ensuring the wastewater is treated to meet environmental discharge standards. This is particularly important for ensuring safe water quality before it is released or reused.

Odor Control: Chlorine dioxide effectively controls odors in wastewater by oxidizing compounds like sulfides, which is critical in power plants where wastewater can generate significant odor issues.

Oxidizing Contaminants: Sodium chlorite can break down organic pollutants, hazardous chemicals, and byproducts such as phenols, thereby reducing overall contamination in wastewater.

Sludge Reduction: Sodium chlorite helps reduce the volume of sludge produced in wastewater treatment by oxidizing organic matter. This not only minimizes the waste generated but also reduces the environmental impact and disposal costs associated with sludge.

Color Removal: Sodium chlorite can be used in some cases to remove color from wastewater, improving the aesthetic quality of effluent water and ensuring compliance with environmental regulations.

Incorporating sodium chlorite into water treatment programs for both cooling water treatment and wastewater treatment allows power plants to effectively manage microbial growth, control odors, maintain system efficiency, and meet stringent environmental discharge requirements.

Get top-quality sodium chlorite and chlorine dioxide products, along with custom solutions. Our expert team is here to help - contact us today!

Contact Us